NEWS

NEws

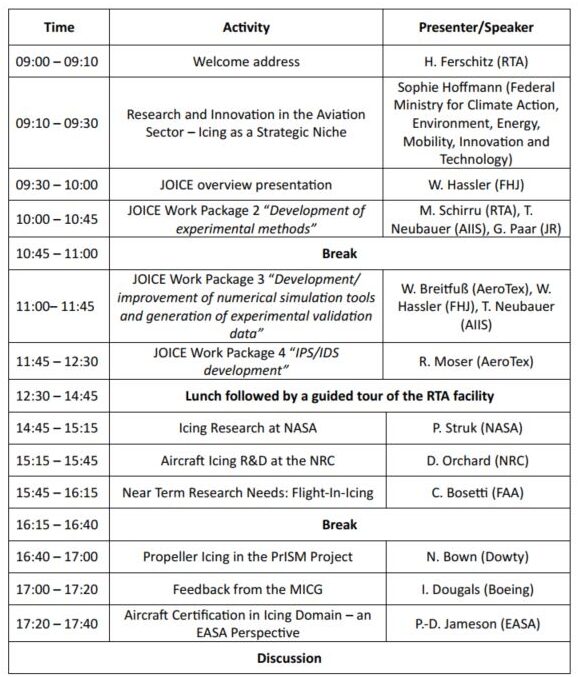

The JOICE public workshop will be hosted at the premises of Rail Tec Arsenal in Vienna, Austria and is open to interested parties free of charge. In the morning, the main outcomes and highlights of the Austrian flagship R&D project JOICE will be presented, followed by a tour through the climatic wind tunnel of RTA. The afternoon program of the workshop will feature presentations and discussion with international icing experts.

The final consortium meeting of JOICE is taking place on Wednesday, 20th of March 2024 at Rail Tec Arsenal in Vienna. The internal meeting will focus on reviewing and discussing the results of the project, lessons learned and identifying possible future research areas in the field of icing.

The Aviation Forum Austria took place from September 28 to September 29 2023 in Vienna. The event was very well attended and under the participants were high-ranking represantitives of the Republic of Austria, as well as many businesses and research institutions. It was jointly organized by the BMK, the FFG, the WKO - ARGE AICAT, AIA, ecoplus and the Holzcluster Steiermark for the first time under the motto "TECHNOLOGY - COOPERATION - GREEN SKY". Many interesting topics were presented and discussed as part of the program of the event, such as “International Cooperation for Efficiency and Sustainability”, “Bridging Today & Tomorrow”, “Circular Economy and New Technology Solutions for Aviation”, and “Gearing Policy & Technology – Challenges & Opportunities”. It was also a great forum to network and exchange ideas for future reserach and development activities. The consortium members of JOICE were delighted to participate in this years Aviation Forum. Thanks to FFG for highlighting JOICE and the work which is performed by the Austrian Icing Community during the event! More information about the Aviation Forum can be found on the FFG website via the following link: https://www.ffg.at/aviation-forum-austria-2023.

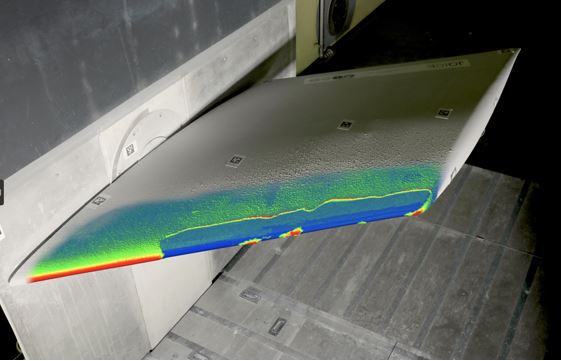

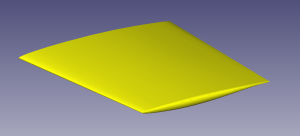

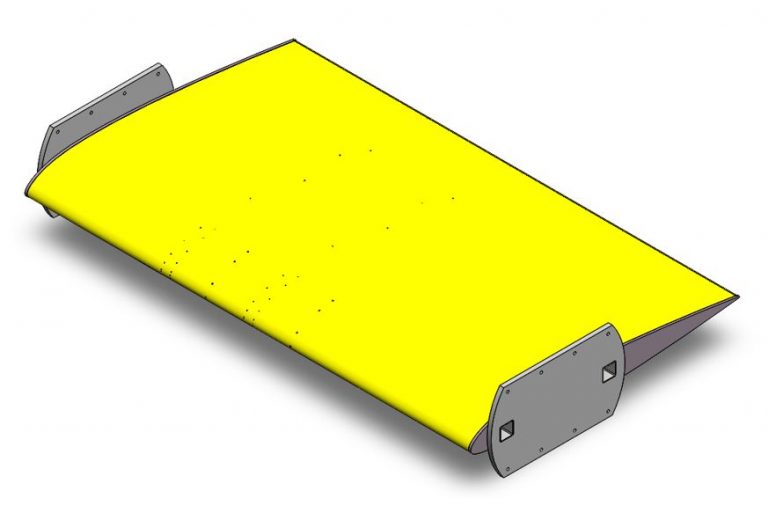

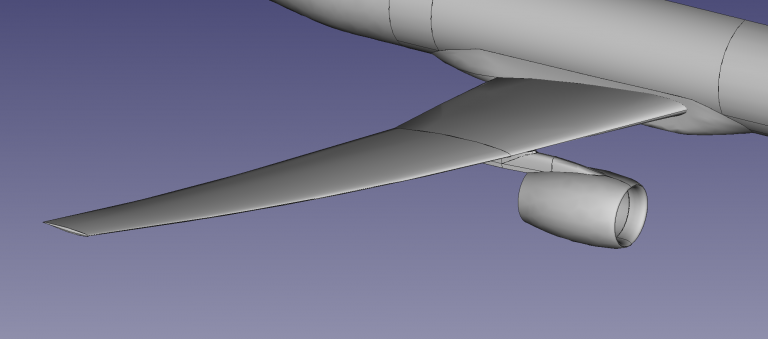

Research institutes and companies are currently working on 3D numerical icing tools for the prediction of ice shapes on an international level. Due to the highly complex flow situation, the prediction of ice shapes on three-dimensional surfaces represents a challenge. An essential component for the development and subsequent validation of 3D ice accretion codes are detailed experimental data from ice shapes accreted on relevant geometries, like wings of a passenger aircraft for example. As part of the Republic of Austria funded research project JOICE, a mockup of a wingtip, based on the National Aeronautics and Space Administration common research model CRM65 was designed and manufactured. For further detailed investigation of electro-thermal de-icing systems, various heaters and thermocouples were included. The mockup was investigated in the Icing Wind Tunnel of Rail Tec Arsenal in Vienna, Austria under various Appendix C and Appendix O icing conditions with and without activated heating systems. The resulting ice structures were documented and analyzed by using 3D and 4D scanning systems. This paper provides information about the design of the mockup, the test setup in the Icing Wind Tunnel well as the applied documentation procedures. Furthermore, an overview of the conducted experimental investigations is given, and selected results and evaluations are presented. The publication is available under the following DOI: https://doi.org/10.4271/2023-01-1386.

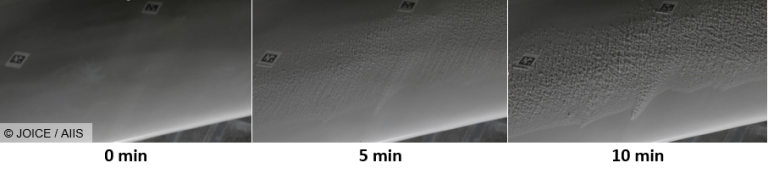

As part of project JOICE, another publication titled “Time Resolved 3D Scanning of Ice Geometries in a Large Climatic Wind Tunnel” was presented at the SAE Icing Conference 2023 in Vienna. In the scope of development or certification processes for the flight under known icing conditions, aircraft have to be tested in icing wind tunnels under relevant conditions. The documentation of these tests has to be performed at a high level of detail. The generated data is used to prove the functionality of the systems, to develop new systems and for scientific purposes, for example the development or validation of numerical tools for ice accretion simulation. One way of documenting the resulting ice geometry is the application of an optical 3D scanning or reconstruction method. This work investigates and reviews optical methods for three-dimensional reconstructions of objects and the application of these methods in ice accretion documentation with respect to their potential of time resolved measurement. Laboratory tests are performed for time-of flight reconstruction of ice geometries and the application of optical photogrammetry with and without multi-light approach. The results of the pre-tests and the review of existing methods are evaluated with respect to scaling of the methods for application in a large icing wind tunnel. As a result of this process, multi-view photogrammetry is used for 3D reconstruction of ice accretion on a common research model wing tip installed in the icing wind tunnel of Rail Tec Arsenal. The results are compared with 3D laser scans of the final ice geometry. The presented approach allows a time resolved quantitative documentation of an icing process without interrupting the experimental ice accretion process.

DOI: https://doi.org/10.4271/2023-01-1414

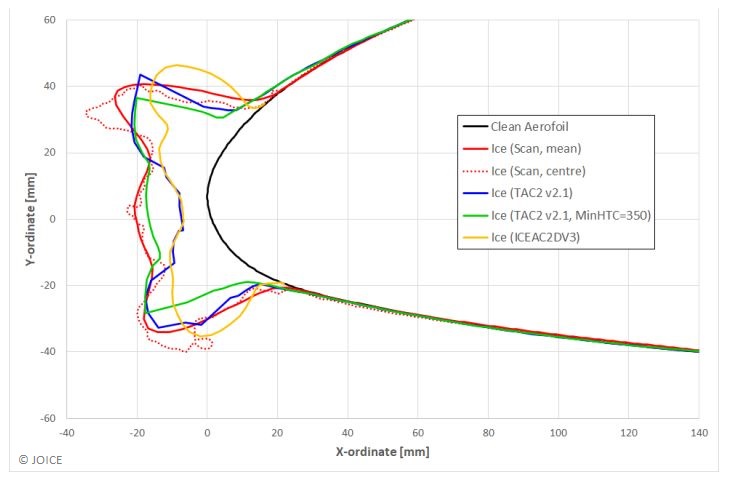

The publication was presented at the SAE 2023 International Conference on Icing of Aircraft, Engines, and Structures in Vienna, Austria by members of the JOICE Consortium. It provides information on the comparison of numerical simulations with experimental data for an electrothermal ice protection system with a focus on Appendix O Freezing Drizzle (FZDZ) and Freezing Rain (FZRA) conditions. The experimental data is based on a test campaign with a 2D NACA23012 wing section in the RTA Icing Wind Tunnel in Vienna. 22 icing runs (all either unheated or in anti-ice mode) were performed in total and all residual ice shapes were documented by means of high-resolution 3D scanning. Unheated FZDZ and FZRA reference as well as heated cases with different heater configurations are presented. The experimental results are compared to numerical predictions from two different icing codes from AeroTex GmbH (ATX) and the University of Applied Sciences FH JOANNEUM (FHJ) in Graz. The current capabilities of the codes were assessed in detail and regions for improvement were identified. Overall, the codes were able to predict the ice shapes of both the unheated and heated cases with reasonable accuracy but both codes overestimated the thickness of the runback ice ridges throughout all cases. The biggest deviations in terms of the position of the ice accretions were seen on the lower surface; on the upper surface a better match was observed. DOI: https://doi.org/10.4271/2023-01-1396

An eventful week for the icing community took place in Vienna, Austria. It started on Sunday 18th of June with the SAE AC-9C Aircraft Icing Technology Committee Meeting, in which various icing topics were discussed by international experts. The meeting was hosted at Rail Tec Arsenal and ended on Monday, the 19th of June in the afternoon with a tour through the test facility including an exhibition from JOICE partners and stakeholders from the Austrian Icing Community. On the next day, the SAE International Conference on Icing of Aircraft, Engines, and Structures began, which lasted from 20th to the 22nd of June. The conference program featured keynotes by industry experts, aviation authorities, as well as presentations about a wide range of research topics in the field of icing. The BMK, the Federal Austrian Ministry on Climate Action, Environment, Energy, Mobility, Innovation and Technology, also gave a keynote on its position with respect to research and development activities in the field of icing, and its FFG Take Off program. The JOICE consortium presented results from its ongoing work which were met with great interest. All in all, the conference was a great success and marked a new record in terms of participants.

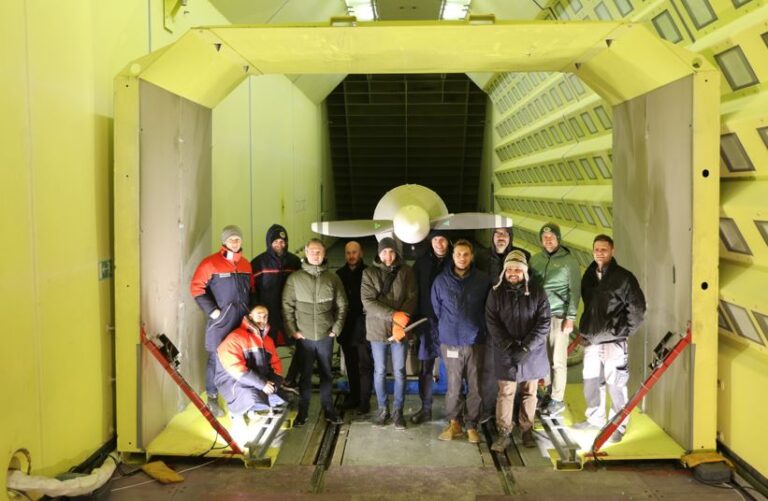

After finalizing the preparation work, the moment for the experimental icing tests with the Prop-Rig at Rail Tec Arsenal in Vienna, Austria finally arrived. An aircraft propeller with 1.80 meters in diameter was investigated in various icing conditions at temperatures from -5°C to -15°C. The rotational speed for the investigated runs was between 1500 rpm and 2000 rpm. Of special interest were the performance degradation and the documentation of ice shedding events with a high-speed camera system. Ice shedding from propellers is highly relevant for the safety and operation of commercial aircraft as well as future urban air mobility applications. A lot of valuable data, which will be processed and analyzed in more detail in due time, could be generated by the JOICE consortium.

The annual JOICE advisory board meeting took place online. After a short introduction, a brief recap of the JOICE work packages and time schedule was given. An overview of the work progress was presented by the consortium, which was followed by three more detailed presentations. Those were:

- Update on the RTA Rotor-Popeller Rig (PropRig)

- Results of the 2D and 3D validation test campaign in the RTA icing wind tunnel

- Ab initio numerical simulation of ice roughness

The JOICE consortium met at the Rail Tec Arsenal in Vienna to do an internal review of the performed work within each of the project work packages. Upcoming tasks and activities were discussed to coordinate the joint effort. Also, potential JOICE publications for the SAE icing conference 2023 were a subject.

The SAE AC-9C meeting was held in Belfast, Ireland from 19-21 September 2022. Members of the JOICE consortium and the Austrian Icing Community were participating in the meeting and discussing latest research results and icing related aviation standards with international experts.

A joint paper was published at the AIAA Aviation Forum 2022 as part of project JOICE. The paper provides information on the generation of validation data for electrothermal ice protection system numerical tools, based on testing on a 2D wing section at the RTA test facility in Vienna. Updates to the RTA calibration capability are provided, including for the Freezing Rain, MVD > 40 microns regime. Latest developments in ice shape scanning and post-processing are shown, including for runback ice generated from heated cases. Some preliminary comparisons to the measured data are provided using different simulation tools, including unheated ice shapes. DOI: https://doi.org/10.2514/6.2022-3457

The AIAA Aviation Forum 2022 is taking place in Chicago, IL from June 27 to July 1 and members of the JOICE consortium are at the event. Get in touch if you would like to meet and exchange about the project.

From 4-6 April 2022 the SAE Aircraft Icing Technology Committee was held in San Diego, USA. One of the plenary sessions at the SAE AC9C meeting featured an update about the ongoing Austrian R&D projects. As part of this, the progress made in JOICE was presented.

The project partners held a meeting and provided an update about the conducted activities and tasks. One key aspect in the meeting was to review the successfully performed icing tests with the 3d wing. Furthermore, the upcoming project work was discussed to coordinate the next steps.

During the icing tests with the 3D wing mockup a newly developed prototype of a 4D scanning system for the documentation of ice accretion processes was tested for the first time in a representative environment. The system, which combines various methods and techniques from 3D scanning and imaging, enables the time-resolved documentation of the ice accretion process on aircraft structures. This is a novelty, as it provides detailed insights into the complexities of icing processes from a new perspective.

At the beginning of 2022 the icing tests with the 3D wing mockup were carried out at RTA in Vienna. The mock-up, a wingtip section of the NASA CRM65 with a span of 1.5 meters, was provided by AIIS and included an electrothermal ice protection system from ATT. The icing tests were a success and valuable validation data could be generated. The test conditions were derived from Appendix C and Appendix O icing conditions according to Certification Specifications for Large Aeroplanes (CS-25) by EASA. Icing was performed at velocities up to 50 m/s and temperatures as low as -20°C.

After the first year of project JOICE the project partners and the advisory board held a virtual meeting to review the progress made and to discuss the next planned activities.

On November 22, 2021 the Austrian Government announced a nation wide lockdown due to increasing COVID cases. For this reason, the for December planned icing tests with the 3D wing mockup have been rescheduled for January 2022. The JOICE consortium is looking forward to the tests!

On November 25, 2021 a talk by Prof. Yee Kwanjung from the Seoul National University (SNU) about the phenomena of aircraft icing was held in front of an international audience. The activities of SNU and its Aerospace Vehicle Design Laboratory (AVDL) were presented. SNU is a project partner in JOICE and contributes to the development and implementation of numerical methods. The AVDL has been investigating various research subjects in the field of numerical simulation, such as aircraft/high-speed train icing, helicopter aerodynamics, and multi-discipline design optimization.

The first icing tests with the 2D wing mockup were conducted in the large icing wind tunnel at Rail Tec Arsenal in Vienna in September 2021. The test conditions were derived from Appendix C and Appendix O icing conditions according to Certification Specifications for Large Aeroplanes (CS-25) by EASA. Icing was performed at velocities up to 80 m/s and temperatures as low as -20°C. The experimental investigation was a great success. Validation data for different icing conditions without heating (unprotected) and with heating (anti-ice system) for the tested specimen were generated. The ice accretion was also documented by means of 3D laser scanning.

The 2D and 3D wing mockup are being manufactured for the icing tests at Rail Tec Arsenal and will be finished according to schedule. Both mockups have integrated instrumentation for the measurement of pressure and temperature on various pre-defined positions on the wing. Furthermore, a heating system is embedded in the leading edge of each wing mockup, which is divided into separate zones. Each zone can be controlled and activated individually. As a result, many different test setups can be tested with the mockups.

One of the main goals of JOICE is the improvement of simulation tools for icing and the generation of validation data. Therefore, a series of icing tests was performed at the icing wind tunnel of FH JOANNEUM with a small scale NACA 23012 airfoil section. The airfoil section was exposed to different icing conditions during the experimental tests, which resulted in glaze and rime ice accretion. The final ice accretion was documented by means of 3D laser scanning and with photographs. The experimental results were compared to results obtained with simulations of various icing codes

At the Institute of Aviation of the FH JOANNEUM University of Applied Sciences in Graz an evening lecture was held on 8th of June 2021. After a general introduction to the phenomena of in-flight icing, project JOICE was presented, following an interesting discussion and exchange of experiences with in-flight icing. About 50 persons attended the evening lecture.

From 19 to 23 of April 2021 the SAE AC-9C Aircraft Icing Technology Committee meeting was held. SAE is a worldwide active association and standards developing organization for engineering professionals in various industries. The AC-9C Committee is focusing on developing standards and recommended practices in the area of aircraft icing. As part of the meeting, project JOICE was presented to the committee of international experts.

As part of JOICE a 2D wing mockup and a 3D wing mockup will be manufactured and tested in the RTA icing wind tunnel under relevant conditions. The mockups will be used to generate validation data for the numerical methods developed within the project and included in the validation database. For the 2D wing mockup a NACA 23012 geometry was selected. The 3D wing mockup will be a 65% scaled wingtip section of the NASA common research model.

Dowty Propellers, one of the world's leading manufacturers for integrated propeller systems, joins project JOICE as advisory board member.

The scope of the project and the planned research and development work was presented to the international advisory board.

The official kick-off meeting with all involved project partners was held and the upcoming project work reviewed. It was a succesful launch of the three year long project.